Laser perforation and cutting sandpaper for skateboard grip tape

Laser is suitable for perforating and cutting sandpaper

Applicable industry:

skateboard non-slip sanding grip tape (sandpaper is consumables)

What are the advantages of laser processing?

Contactless process

Clean and smooth cutting edges, no burrs on the edges, no reworking necessary. No tool wear – consistently high quality.

Precise process

Produces intricate patterns and fine details. Superior part quality that cannot be replicated using the die cut process.

No punching dies needed

High degree of flexibility in the choice of any shapes and designs – without any need for tool construction or changeover.

What are the advantages of laser perforating of sandpaper?

GOLDEN LASER develops special laser machines for sandpaper

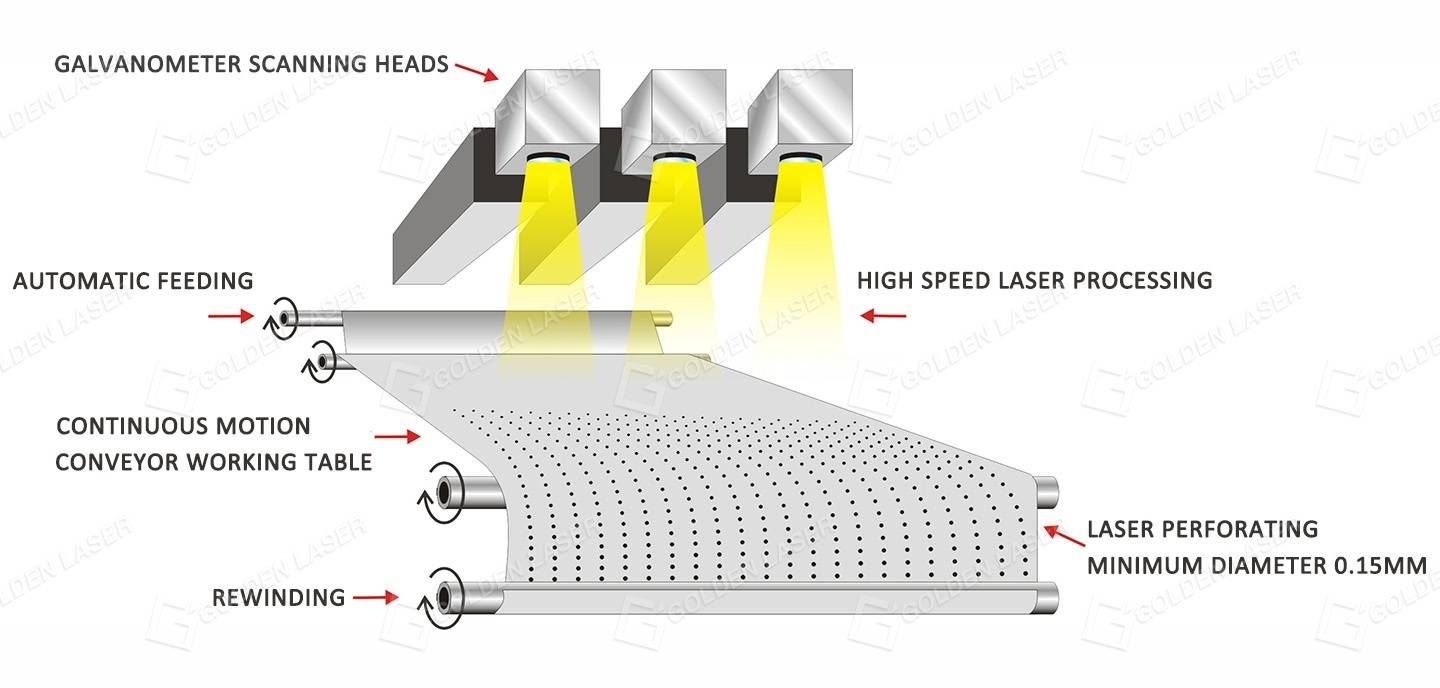

Ⅰ. High Speed Laser Perforation Machine ZJ(3D)-15050LD

- To Perforate micro-holes on sandpaper. Roll to roll processing.

Ⅱ. LASER CROSS-CUTTING MACHINE JG-16080LD

- To cut rectangle across the width of the roll of sandpaper

- X-axis movement on gantry

- Working area 1600mm width, 800mm length

- with 1200mm extended table

- 180W laser power, CO2 glass laser tube

- Particle slot design, the finished particles falling inside

What type of laser?

We have a complete laser processing technology, including laser cutting, laser engraving, laser perforating and laser marking.

What is your material?

Test your materials, optimize the process, provide video, processing parameters, and more, free of charge.

What is your industry?

Digging deep into industries, with automated and intelligent laser application solutions to help users innovate and develop.