Cutting and Perforating Holes of Textile Ventilation Ducts with Laser

Lightweight, noise absorption, hygienic material, easy to maintain, all these features have accelerated the promotion of the fabric air dispersion system in the past decade. As a result, the demand for fabric air dispersion has been increased, which challenged the production efficiency of the fabric air dispersion factory.

Precise and high-efficiency of laser cutting can simplify the procedures of processing fabric.

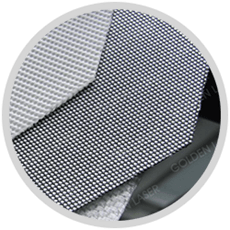

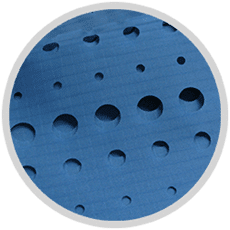

For air dispersion applications, there are mainly two typical materials, metal and fabrics, traditional metal duct systems discharge air through side-mounted metal diffusers. The air is directed to specific zones resulting in less efficient mixing of air in the occupied space and often causing drafting and hot or cold spots; while the fabric air dispersion has uniform holes along with the entire length dispersion system, providing consistent and uniform air dispersion in the occupied space. Sometimes, micro-perforated holes on slightly permeable or impermeable ducts can be used to deliver air intensively at a low velocity. Uniform air dispersion means better air mixing which brings better performance for those areas that need ventilation.

The air dispersion fabric is definitely a better solution for ventilation while it is a big challenge to make the constant holes along the 30 yards long or even longer fabrics and you have to cut the pieces out besides for making the holes. Only laser can realize this process.

Goldenlaser specifically designed CO2 laser machines that fulfill the exact cutting and perforating of textile ventilation ducts made of specialty fabrics.

Benefits of Laser Processing Textile Ventilation Ducts

Smooth and clean cutting edges

Cutting the dispersion holes constantly matching the drawing

Conveyor system for automatic processing

Applicable Materials

Types of Common Fabric Duct Materials for Air Dispersion Suitable for Laser Cutting and Perforating

Polyether Sulfone (PES), Polyethylene, Polyester, Nylon, Glass Fiber, etc.