Laser Cutting of Synthetic Textiles

Laser Cutting Solutions for Synthetic Textiles

Laser cutting machines from GOLDENLASER are extremely flexible, efficient and fast for cutting all kinds of textiles. Synthetic fabrics are textiles made from man-made rather than natural fibers. Polyester, acrylic, nylon, spandex and Kevlar are some examples of synthetic fabrics that can be processed particularly well with lasers. The laser beam fuses the edges of the textiles, and the edges are automatically sealed to prevent fraying.

Leveraging its many years of industry knowledge and manufacturing experience, GOLDENLASER develops, manufactures and supplies a wide range of laser cutting machines for textile processing. They are designed to provide textile product manufacturers or contractors with the state-of-the-art laser solutions to enhance their competitive edge and help them to meet end-use requirements.

Laser processing available on synthetic textiles:

1. Laser cutting

The energy of the CO2 laser beam is readily absorbed by the synthetic fabric. When the laser power is high enough, it will cut through the fabric completely. When cutting with a laser, most synthetic fabrics vaporize quickly, resulting in clean, smooth edges with minimal heat-affected zones.

2. Laser engraving (laser marking)

The power of the CO2 laser beam can be controlled in order to remove (engrave) the material to a certain depth. The laser engraving process can be used to create intricate patterns and designs on the surface of synthetic textiles.

3. Laser perforation

CO2 laser is capable of perforating tiny and accurate holes on synthetic fabrics. Compared to mechanical perforation, laser offers speed, flexibility, resolution and accuracy. Laser perforation of textiles is neat and clean, with good consistency and no subsequent processing.

The benefits of cutting synthetic textiles using lasers:

The Advantages of goldenlaser’s laser cutting machines for fabric:

Material information for the laser cutting of synthetic textiles:

Application examples synthetic textiles:

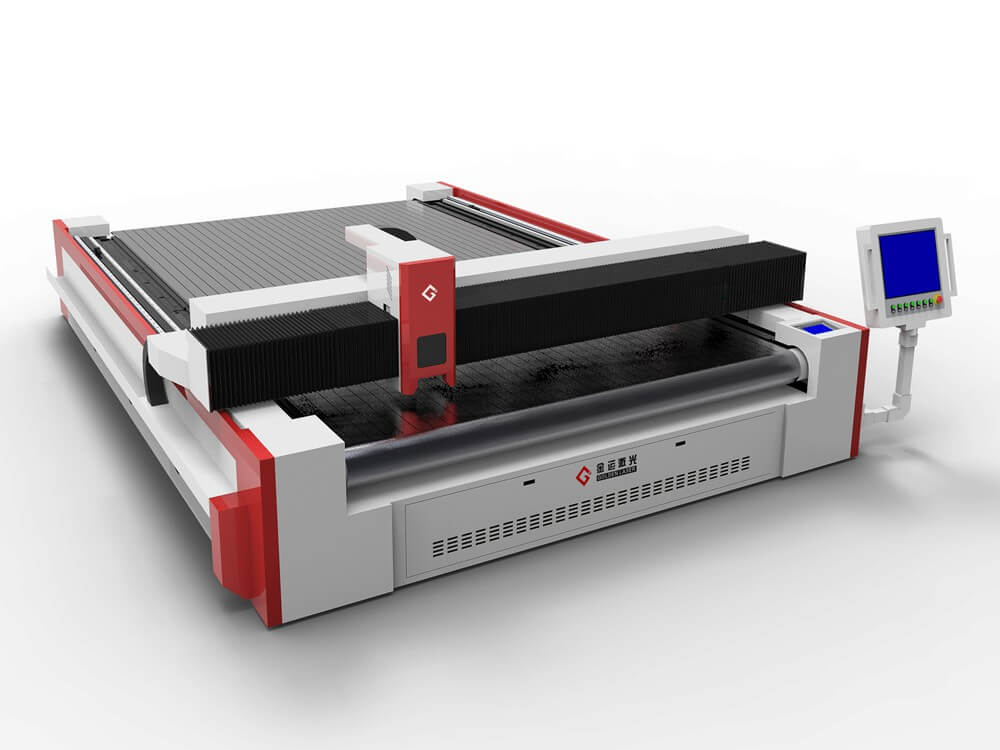

We recommend the following goldenlaser systems for the cutting of synthetic textiles:

Large Format Flatbed CO2 Laser Cutting Machine

Galvo & Gantry CO2 Laser Engraving Cutting Machine

MARS Series CO2 Laser Cutter Machine

Looking for additional information?

Do you have questions or are there technical matters you would like to discuss? If so, you are very welcome to contact us! Please just complete the form below. Our specialists are always happy to help and will get back to you promptly.